Comment Sony and Fujifilm this month settled a festering legal dispute that crippled the global supply of LTO-8 tape media.

The terms of the settlement are secret and neither side are talking. But it will take months to fulfil backlogged LTO-8 tape media orders and customers could wait until next year to get their cartridges, according to our sources.

Here is our take: Sony and Fujifilm have behaved disgracefully and held an entire industry to ransom. This must not happen again.

The companies are the only two tape media manufacturers in town and they have been at each other’s legal throats with a succession of IP lawsuits and US LTO-8 media import bans.

Their lengthy dispute has held up LTO-8 tape media supply for months, rendering LTO-8 tape technology useless. In turn this has led many to doubt the reliability and trustworthiness of tape-based backup and archiving at a time when disk and flash-based alternatives are becoming more attractive.

The tape backstop

Tape for IT has two main uses: longer term mainframe data storage and general server backup and archiving.

The LTO tape market exists because customers store backup and archive data on tape. It is less expensive than disk or flash systems and it is reliable enough.

LTO tape formats are for the backup and archiving of general X86 servers. The latest tape storage standard is LTO-8, with 12TB raw capacity. It succeeded the previous LTO-7 with its 6TB raw capacity.

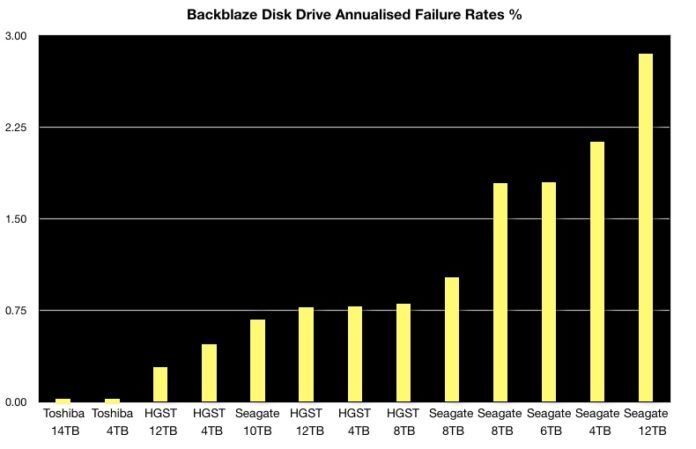

However, disk-based backup and archive storage is becoming more viable as the cost/GB decreases with rising disk capacity. Retrieving data from disk is faster than retrieval from tape.

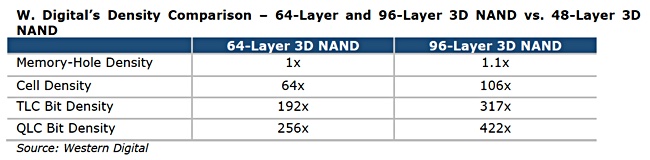

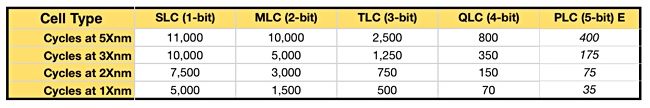

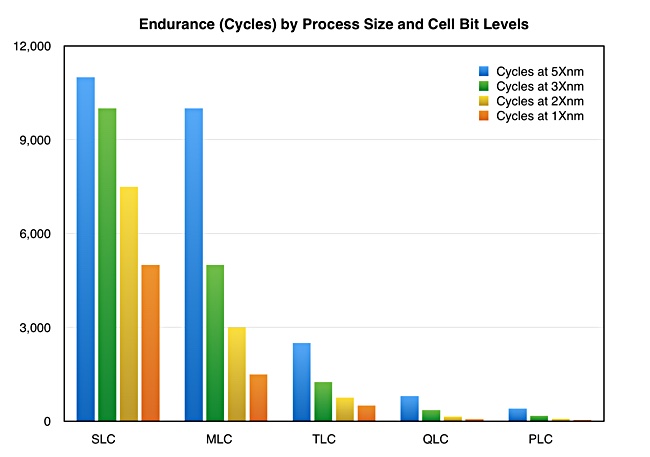

Similarly with flash, where QLC (4 bits/cell) and the potentially coming PLC (5-bits/cell) technologies are lowering the cost/GB of flash to the point where fast access archive using flash are possible.

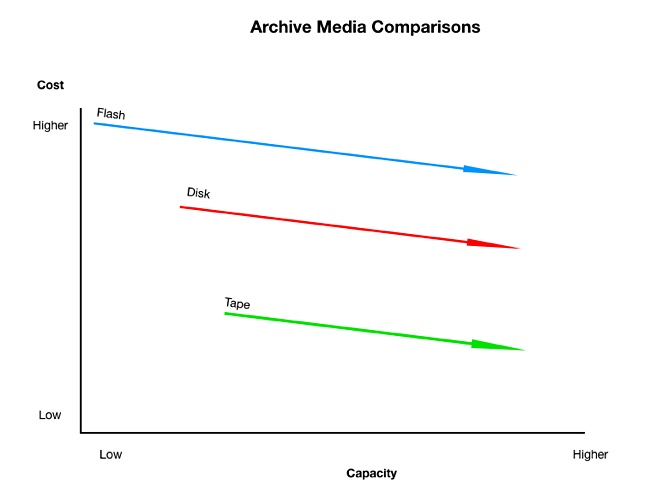

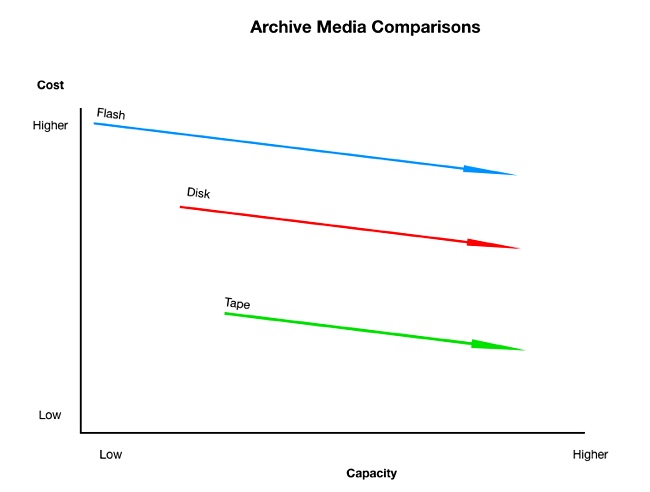

So we have three technologies varying in cost and speed:

- Tape – lowest cost and slowest speed

- Disk – medium cost and medium speed

- Flash – highest cost and highest speed

There is equilibrium so long as technology development in each medium does not upset the balance between the media.

If there is a significant tape media supply interruption then equilibrium weakens and the slack is picked up by disk and flash alternativies.

The dispute

The general Fujifilm-Sony legal dispute dates back to 2016 when Fujifilm complained to the United States International Trade Commission (USITC) that Sony was infringing a dozen or so of its tape media patents. The USITC opened investigations and in March last year decided Fujifilm was right and banned Sony from importing tape media, including LTO-7 cartridges, into the USA.

Sony went to the Patent Trial and Appeal Board (PTAB) to counter the Fujifilm accusations and won. Fujifilm then appealed to the US Court of Appeals for the Federal Circuit against the PTAB decision.

In March this year a USITC order (PDF) prevented Fujifilm from importing certain LTO tape cartridges and in May the US Court of Appeals for the Federal Circuit decided Sony was in the right.

So, effectively, LTO-8 tape cartridge supply dwindled to a trickle globally and was halted in the USA.

Secret resolution

Now the dispute is over, but the terms of the settlement between Fujifilm and Sony are secret. There is no excuse for this. What is to stop the two companies doing this again?

The LTO (Linear Tape Open) organisation has three Technology Provider Companies; HPE, IBM and Quantum. They license tape manufacturers to make tape according to LTO standards, such as LTO-7 and LTO-8, which specify tape cartridge capacity and data transfer speeds.

There are only two licensed manufacturers – Fujifilm and Sony – and they form a duopoly. There were others, such as Ampex and Panasonic, but the tape media supply industry has contracted until just two are left.

The reason for having more than one licensed manufacturer is basic; it’s to stop that manufacturer hiking prices and/or fouling up supply. Having more than one discourages this, and there are laws about manufacturers colluding to raise prices.

Even so, it’s easier for two manufacturers to collude than three, easier for three to collude than four, and so on. Two is the minimum you need. But, only having two manufacturers heightens the risk of the two competing in court to enforce their IP claims and trying to prevent each other from selling product based on the other’s patents.

And this is what has happened with the two media suppliers strangling the entire tape archiving ecosystem with their petty IP dispute.

The way forward

We can’t expect other tape media suppliers to spring into existence. Setting up a media manufacturing operation would cost hundreds of millions of dollars and tape recording media area is full of patents which would need to be licensed from the incumbents.

We are stuck with the duopoly of Fujifilm and Sony. How can the tape industry ensure that media supply is not cut off again?

Blocks & Files thinks the LTO has the collective power, ability and responsibility, to negotiate good prices and good behaviour from its tape media suppliers. OEMs. That good behaviour should include cross-licensing of patents.

Sony, Fujifilm and the LTO, should be open about the terms of the settlement they have agreed, and commit to a non-repeat of this petty and ridiculous dispute that everyone in the LTO ecosystem has been forced to endure.