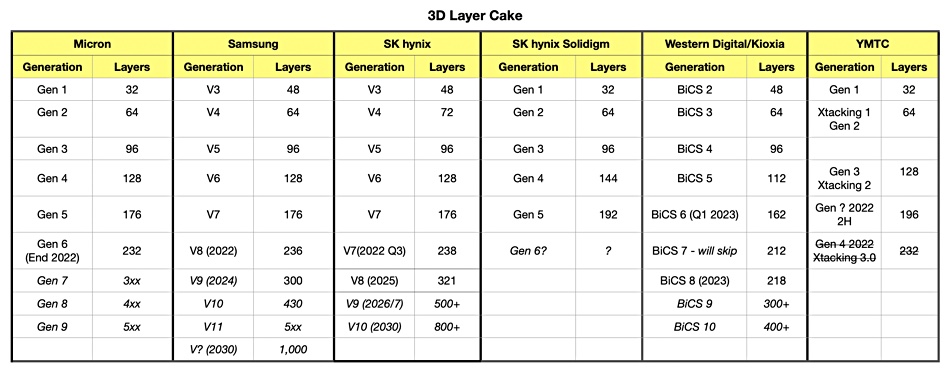

Samsung is planning to build 300-layer3D NAND according to a paywalled DigiTimes Asia report.

This would make Samsung the second 3D NAND fabber after SK hynix to reach the 300-layer point. Sk hynix announced its 321-layer NAND a few days ago at FMS 2023. Micron has a 232-layer tech, SK hynix subsidiary Solidigm is at 192 layers while Kioxia/WD are at the 218-layer level with their BiCS gen 8 technology. China’s YMTC technology progress has been halted due to US IT technology export controls.

Generally speaking, the more layers in 3D NAND, the higher the capacity of the die, assuming the cell dimensions don’t change, and the lower the production cost per TB of flash. This leads to fewer NAND chips being needed to produce flash drives at existing capacity levels, higher-capacity flash drives and, hopefully, a lower cost in $/TB terms.

The 300L Samsung V-NAND device will be made by string-stacking two 150-layer components (strings of cells) together. As more layers are added to a 3D NAND element on a flash wafer it is necessary to etch holes (vias) between layers, and line the holes with chemical substances as part of the die fabrication. These need to be perpendicular to the plane of the wafer and have a regular cross-section and shape as they penetrate the myriad layers involved.

As the layer count increases, it becomes more and more difficult to ensure these characteristics and the yield of the wafer, in terms of good dies versus bad dies, decreases. Stacking two 150-layer components will be easier in manufacturing terms than building a single 300-layer product, although manufacturing takes longer.

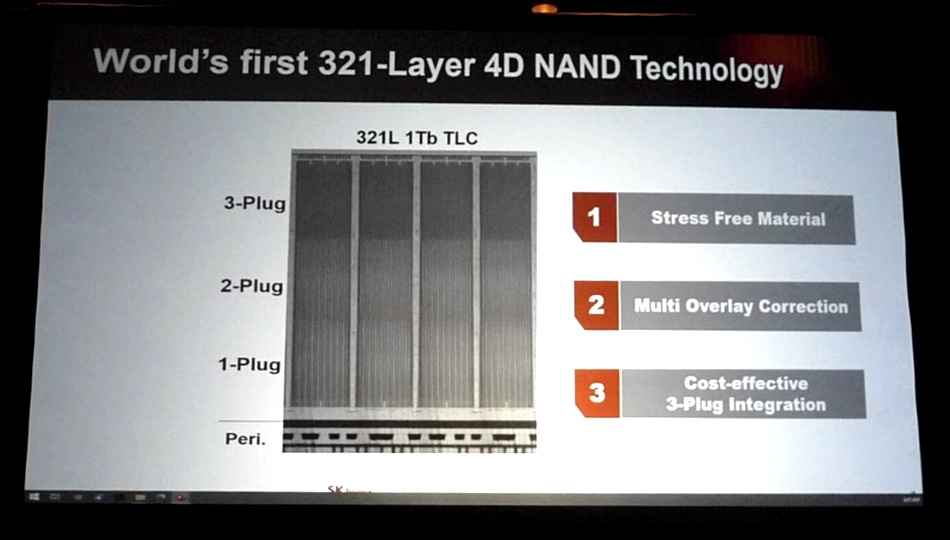

The SK hynix 321-layer product is formed from 3 strings, or plugs, stacked together according to a PC Watch photo of an SK hynix slide shown at FMS 2023. Each string has 107 layers. The existing hynix 238-layer technology has two strings, each with 119 layers.

Samsung’s 10th 3D NAND generation could be a 430 layer die and that could also use 3-string stacking technology.

Micron and WD/Kioxia will be encouraged to move to 300-layer technology because, unless they do, their production costs will be higher than both Samsung and SK hynix, putting them at a price disadvantage. Similarly, SK hynix subsidiary Solidigm will face the same pressures.