Folio Photonics aims to develop an archive optical disk with lower-than-tape cost, terabyte-class capacity, multi-decade life and backwards compatibility through technology generations.

It reckons its technology is simpler to productise than holographic drives and more cost-effective and capacious than Sony’s Optical Disk Archive (cartridge with 11x 550GB disks).

Many companies have tried — and failed — to create an optical disk with tape-level economics and capacity. Remember InPhase, which crashed and burned in 2010? Can Folio Photonics finally develop an optical disk to blow tape out of the archive water?

Technology

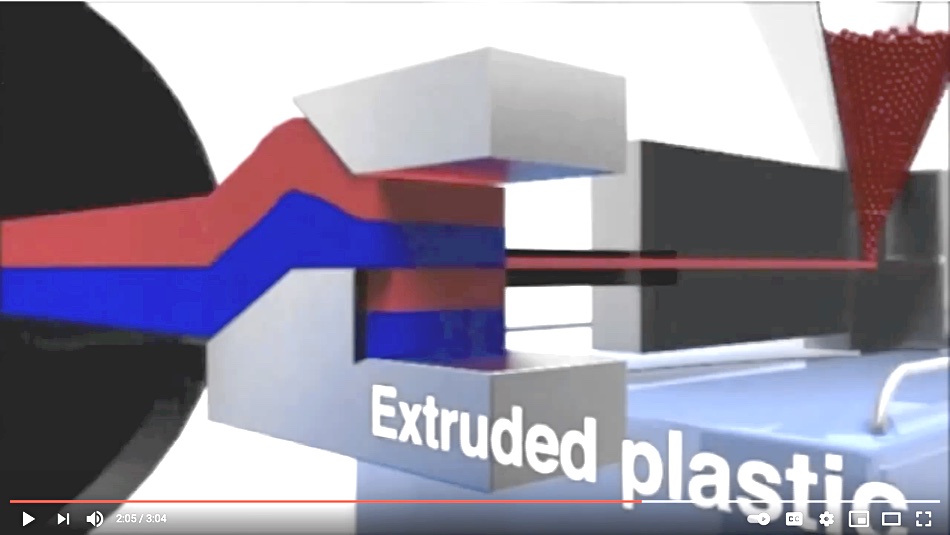

FP’s DataFilm Disk (DFD) technology uses optical disk platters, like Blu-ray, and coats them with a multiple-layered polymer film — a 3-D approach. The layers contain fluorescent dye-doped material and are separated by transparent buffer zones. The polymer film is made in a co-extrusion process with a sequence of splitter/multiplier units, taking a two-layer extruded plastic flow (data layer + buffer layer) at the start and doubling its layer count each time.

A YouTube video shows the process. A final die unit takes the multi-layered plastic flow of film and spreads and thins it into a long ribbon from which disc-sized circles can be cut and affixed (laminated) to platters.

There can be, in theory, 64 or more layers. Data is written in each layer by using a pulsed laser to cause fluorescent photobleaching such that a spot on the layer, a few hundred nanometres in size, is either light (bleached) or dark. The laser light is focused at the right depth in the polymer film to impact a specific layer by passing through a moveable objective lens. Once written the data is unalterable — these are WORM (Write Once Read Many) disks.

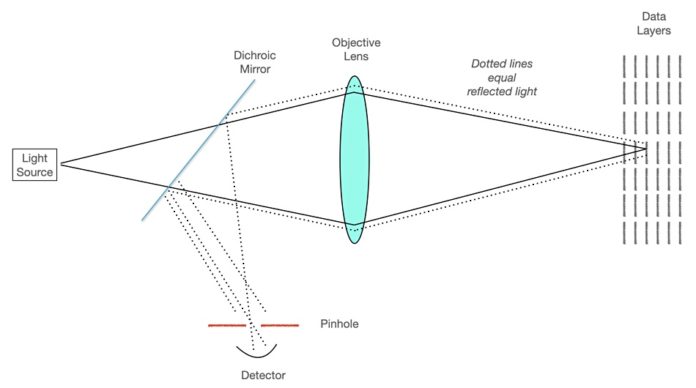

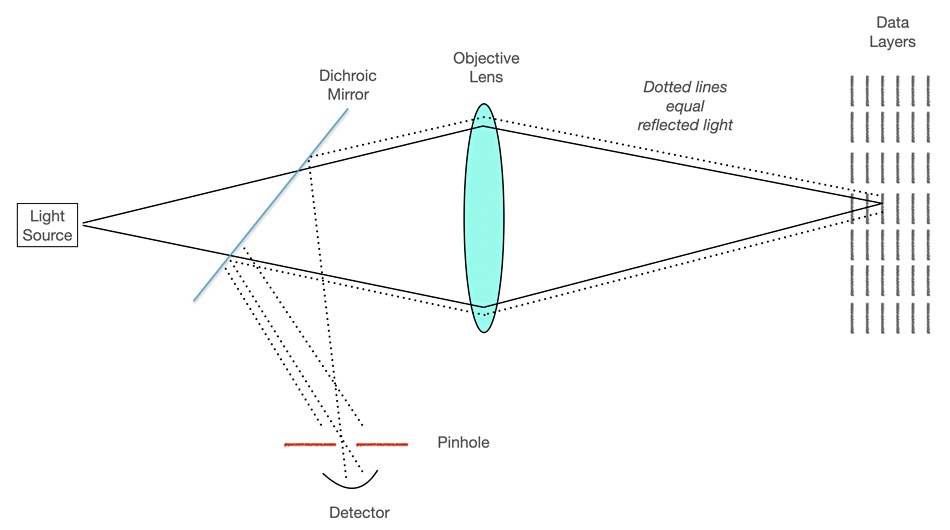

Data is read using a confocal imaging technique as in the diagram below. Laser light is shone at a spot on a rotating disk track, focussed to the right depth for the desired layer, and then the reflected light collected via a dichroic mirror. This reflects to a so-called pinhole with a light detector behind it. Reflected light from the layers above and below the desired data layer will not pass through the pinhole into the detector — its focus will be wrong.

Much of this technology is already used in Blu-ray drives. Basically, adding a pinhole to such a drive would be the essence of a DFD read head or Optical Pickup Unit (OPU).

Business development lead Travis Jonston tells us “Our data would be stored as binary. It would consist of a dark on light writing strategy where reading either bleached or fluorescent spots would act as the binary signals. Our data rate is ~365MB/sec and our time to first bit is ~15s although this could be manipulated with the number of drives put into a library.“

Business case and roadmap

FP’s cost modelling indicates that its DFD will upend the data archiving industry by lowering annual media acquisition costs over incumbent technology by up to a factor of 50 in the next decade.

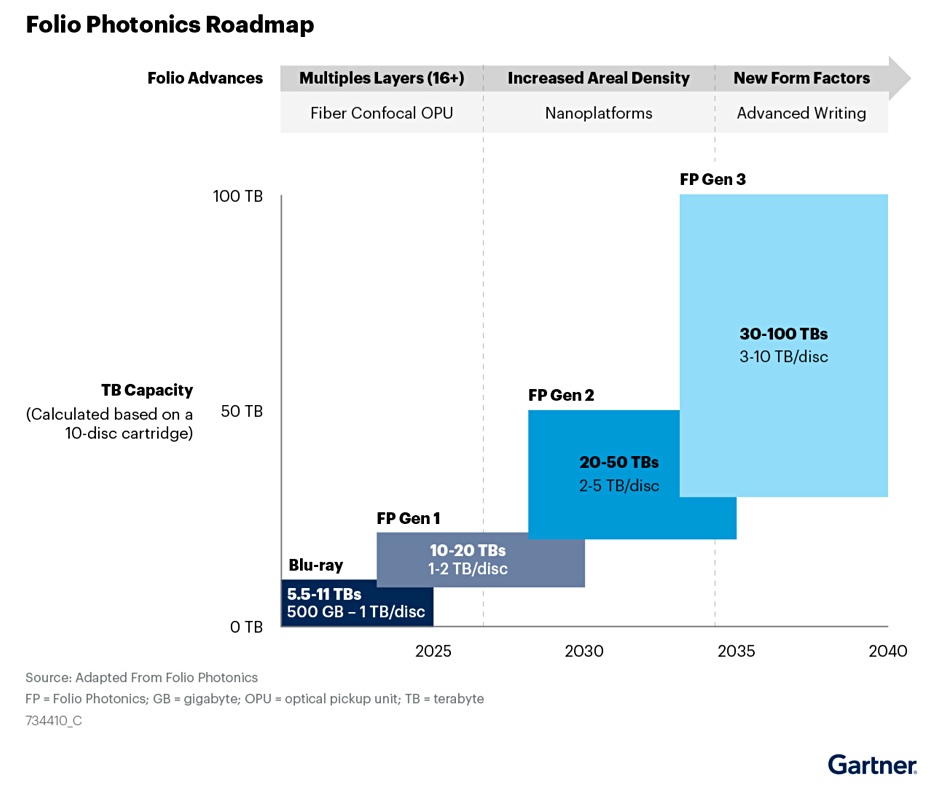

Gartner analyst John Monroe points out in an emerging tech document: “Folio Photonics is now poised to deliver its new optical technology, enabling eight or 16 film layers per side per disc (as opposed to only three optical layers per side per disc for Sony’s and Panasonic’s AD). … The company plans to ship 10 to 20 terabyte cartridges (containing 10x one- to two-terabyte discs) by 2024.”

There are two further DFD generations planned:

- two- to five-terabyte disks in 20 to 50TB cartridges, by 2028;

- five- to ten-terabyte disks in 50 to 100TB cartridges, by 2033.

There will be complete backward compatibility.

SpectraLogic’s Data Storage Outlook 2021 document says hard disk drives cost about $25/TB while tape is around $10/TB. Sony’s Optical Data Archive storage costs $45/TB.

DFD cartridges could have $2 to $3/TB acquisition cost and a 100-year-plus shelf life. Generations 2 and 3 could lower the cost/TB towards $1 which could, Gartner thinks, trigger widespread deployment in large data centres.

Sony’s third-generation ODA (double sided disc with triple layer/side) uses 5.5TB cartridges, costing $250, with a 375MB/sec read and 187MB/sec write bandwidth. The DFD’s theoretical data rate performance of 365MB/sec is in the same area and its costs look be a small fraction of the ODA cartridge.

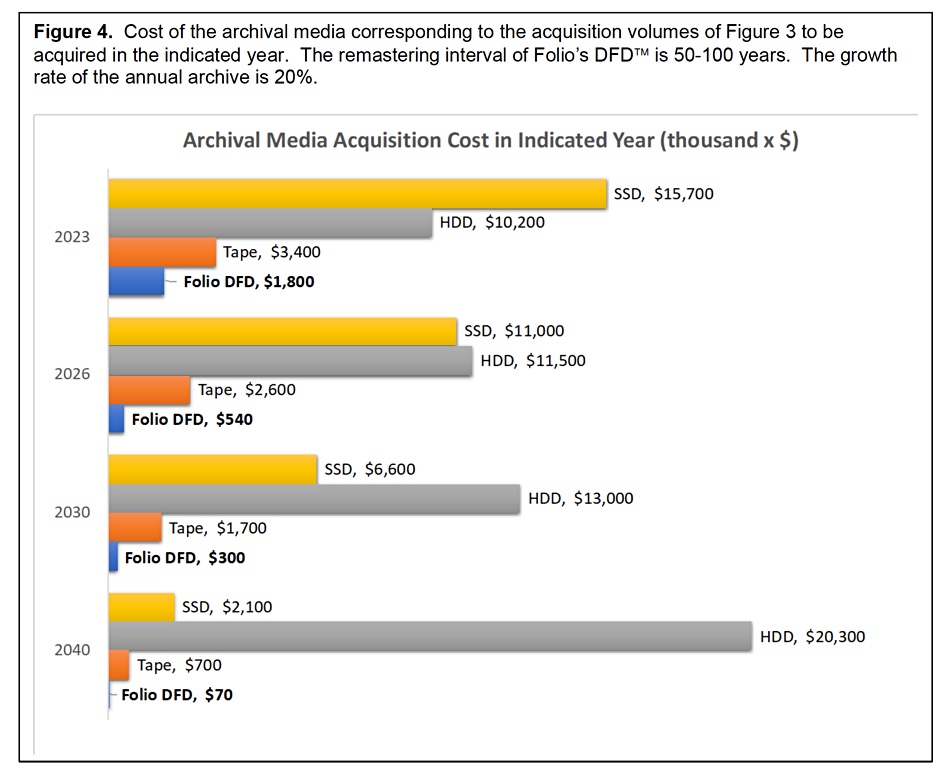

FP has modelled the comparative costs of tape, HDDs, SSDs and its DFD technology. It says the first three technologies, when used in an archive, all require periodic re-mastering — copying to new-generation media — every five years or so (every two generations of LTO tape). DFD archives will only require re-mastering every 50 to 100 years, therefore their media costs will be much lower.

Over a 17-year period (2023 to 2040) the total archive media costs for each technology in its model should be:

- SSD — $35,400;

- HDD — $55,000;

- Tape — $8,400;

- DFD — $2,710.

These are promising numbers but, as yet, we have no product on which to test them.

Company

Folio Photonics was started up in 2012 by Professor Ken Singer of Case Western Reserve University as a spin-off from its Center for Layered Polymeric Systems. It is based in Solon, Ohio, and received a $.2 million venture funding round in 2017 and an $8 million seed round in 2019. There are 14 employees. The company is seeking a third funding round, according to Singer in a June 2020 YouTube video, amounting to between $10 and $15 million.

That would presumably pay for building up the company’s general infrastructure, sales and marketing to introduce its first product, and also to fund the next-generation product — one with more layers and higher capacity.

He says FP is making partnerships with a number of large companies to bring a product to market.

FP had hoped to bring product to market in 2020, in the form of a 16-layer, 750GB disk. Johnston said: “We experienced a setback in 2020 as we were working closely with Sony for the development of our unique optical pickup unit. As our company is mainly chemists/physicists, that was not our expertise. When the pandemic began, our relationship became much harder to maintain without physical travel and a time difference.

“We decided to open our own Optical Division in Colorado, where we now have four optical engineers working to develop the OPU. We believe our current 16-layer discs (1.2TB) to be fully functional, but without the OPU development/testing we cannot state that with 100 per cent certainty. We have the OPU tracking on a one-layer disc and we are hopefully just a few weeks away from 16-layer tracking (which would then give us full proof of concept and demonstrability). Overall, we are looking at 18–24 months before our first commercial product.”

That would be in the 2023–2024 timeframe.

To find out more watch a second video and read an FP white paper. You can also request a copy of a Gartner paper called “Emerging Technologies: New Active/Accessible and Deep Archive Data Requirements — Enterprise Optical Storage Technologies” from FP, and check out the Spectra document above.