Microsoft is using robots to take dead disk drives apart and recycle the parts as part of its e-waste reduction efforts.

Currently hard disk drives at the end of their life are generally shredded to destroy the data held on their platters. Yet the other component parts, such as magnets containing rare metals like neodymium, can be re-used. Total shredding prevents that, turning everything into scrap fragments. Up to 70 million HDDs are destroyed annually, making for a lot of wasted neodymium and other rare metals.

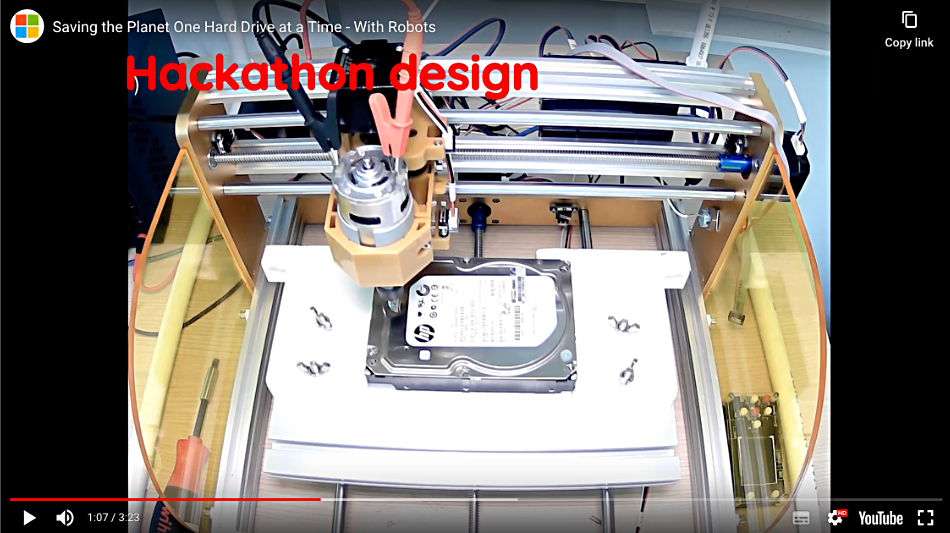

A robot disassembly scheme was devized at a 2020 Microsoft Hackathon in a Secure and Sustainable Disposal of Hard Disks project. The team behind it was led by Principal Data Scientist Ranganathan Srikanth. The project was initiated against a background of Microsoft’s existing Circular Center concept.

A Microsoft video narrative explains that it’s setting up circular centers on its data center campuses and will soon be able to process e-waste on site. It can re-use and repurpose some assets, such as servers, and better dispose of useless ones such as old HDDs. It aims to achieve 90 percent server and parts re-use by 2025. Microsoft’s big goal is zero waste by the end of 2030 and to be carbon-negative by 2050. The circular centers are vital to achieving that.

Srikranth said: “These ‘Circular Centers’ are purpose-built to improve, reuse, and recycle cloud hardware” by repurposing and recycling servers and related hardware.

HDDs containing customer and Microsoft data had to be disposed in away that obliterated the data, and that meant using the shredding method. Sriksanth’s project was aimed at improving on that. It envisaged three stages of smarter HDD disposal: demanufacture by disassembling the disk, destroying the data platters, and recycling everything else.

The disassembly could only be efficiently done at scale by using robot machinery and Srikanth’s team worked up a robot system that did this and then sorted the parts, sending the platters off for shredding.

Another Microsoft video shows viewers how this is done. The video narrator says: “The process uses computer vision and robotics to disassemble the hard disk, sorts them, and destroys the media that contains data. The materials are then recycled.”

“The process starts with detecting the type of hard disk …Screw detection guides the robot to the precise location.”

“Screws are removed from all sides.” and the parts are extracted and sorted.

Once the case is opened: “The parts are recycled and material extracted.”

Then: “The media containing data is securely transported to the shredding unit … The data disks are destroyed while the rest is recycled.”

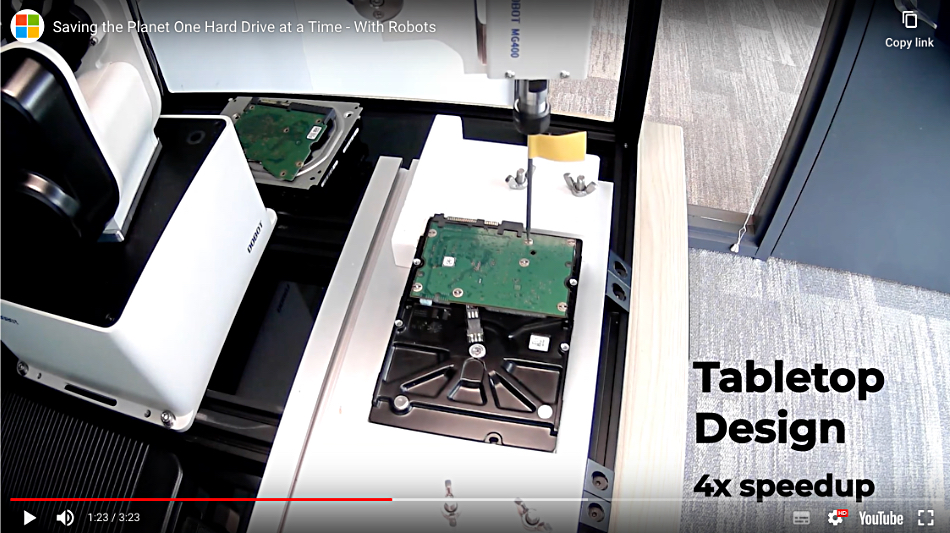

The drive’s printed circuit board is held in place by screws. The robot locates and undoes them so the PCN can be extracted. The video shows the HDD’s printed circuit board having its screws removed by a machine which carries a Dobot Robotics label.

The narrator says: “The magnets and other parts of the hard disk can now be removed.”

Microsoft seem to now have a demonstrable and scalable way of disassembling disk drives, securely destroying the data and re-using or recycling the component parts. We’ll keep you posted on further updates.