Researchers from Japan and Seagate have demonstrated a multi-layer disk drive recording method that could double or triple disk drive capacity in a proof-of-concept study.

Hard disk drive platters have a surface layer of magnetic recording material on which recorded bits are written and read in concentric tracks. The reading and writing is carried out by an actuator device that moves across the disk tracks and operates on the bit areas as the disk spins beneath it. Seagate’s latest Heat-Assisted Magnetic Recording (HAMR) technology writes small bits, with the bit area temporarily raised to a high temperature to permit writing (setting the magnetic polarity direction) then cooling to room temperature for long-term magnetic stability.

The paper – “Dual-layer FePt-C granular media for multi-level heat-assisted magnetic recording” – describes the recording material built by the researchers, its layering, and the theoretical testing of its capabilities. It was written by scientists from Japan’s NIMS and Tohoku University, and engineers from Seagate Technology in Fremont, and is available behind a $43.14 Elsevier paywall.

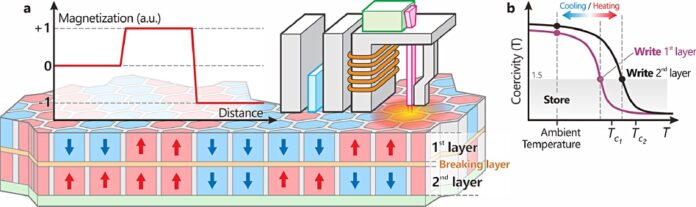

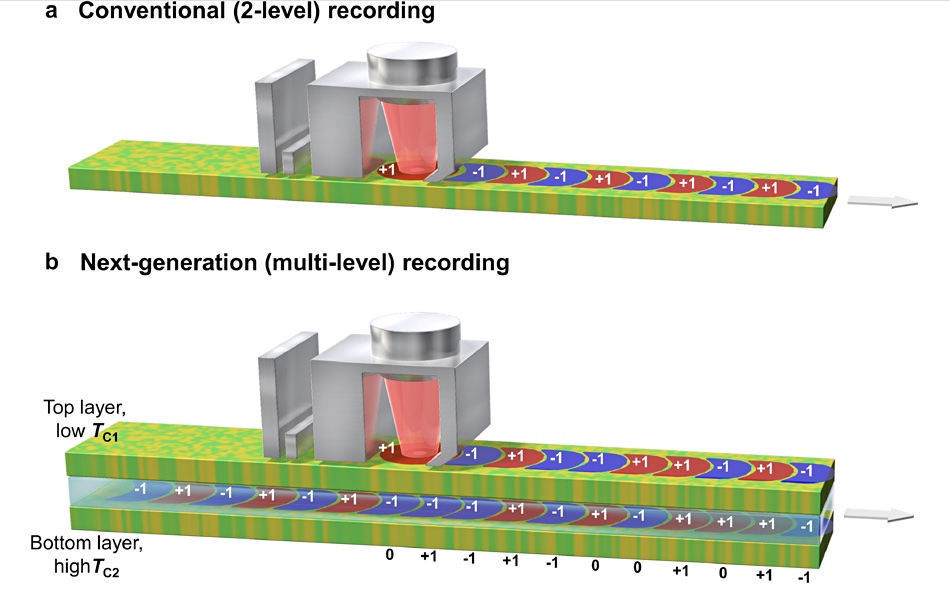

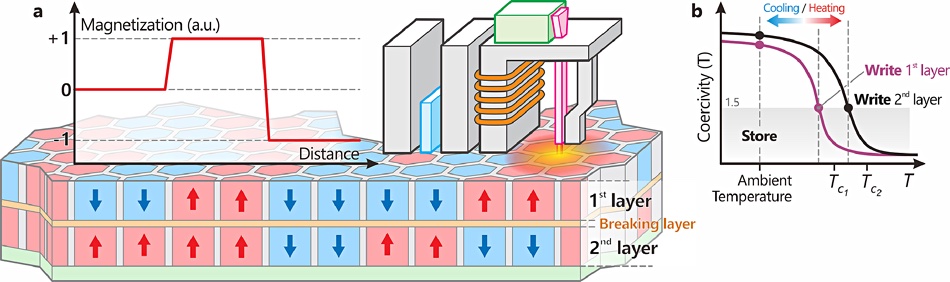

The authors explain conventional HAMR recording, with one layer and two levels. Magnetic north or south corresponding to binary one or zero, and their multi-level, two-layer recording with two four binary levels per layer:

Disk drive capacity has been increased by shrinking the size of the bit areas with their magnetic nano-grains. The existing perpendicular magnetic recording (PMR) technology, which operates at room temperature, runs into a grain size limit, roughly 1 Tbit/in² bit areas, below which the grain’s magnetic polarity is not stable, meaning the disk drive cannot store information reliably. HAMR technology uses a different magnetic recording medium, which is stable at ambient or room temperature, but needs heating to allow its magnetic polarity to be changed. This has enabled the bit regions to be reduced in size to 1.5 Tbit/in² and down to 4 Tbit/in². Beyond that they become unstable as well.

They say that “increasing the areal density of future generations of HDD recording media requires a new recording concept that is not reliant on grain size miniaturization. One solution is bit-patterned media (1 bit = 1 grain) instead of granular media (1 bit = multiple grains). Numerical calculations predicted that bit-patterned media can achieve an areal density of 10 Tbit/in². However, bit-patterned media cannot be mass produced because of their costly nanofabrication process.”

Their idea is to use a two-pass approach with two layers of HAMR recording material, each with different Curie temperatures, at which their magnetic direction can be changed. The laser heats the recording medium’s surface and the surface layer heat penetrates to the lower layer, enabling both layers to be written to the same value. After cooling the surface is heated again but to a lower temperature, which enables the upper layer’s value to be written but not alter the lower layer’s value.

The researchers have demonstrated this two-layer recording material concept, with the HAMR heating laser and write head tuned to be able to operate on the lower layer first and then write the upper layer bit value. This provides four theoretical bit values for any pair of bits in the upper and lower layers: 1-1, 1-0, 0-1, and 0-0.

They started with the recording FePt-C (iron, platinum, and carbon) layers, which are a approximately 5 to 6 nm thick and have a breaking Ru-C ( ruthenium and carbon) layer between them that is half that thickness. A carbon capping layer was applied to prevent surface oxidation.

Electron microscopy photos were taken to inspect the grain structure and the separation between the layers. Finite element model analyses were run to verify the operation of their concept. In other words, the researchers did not build an actual read-write head and test its operation on a spinning platter with their recording medium layers.

In this modelling, “the heat spot was moved along the medium at a velocity of 4 m/s.” The researchers noted “written track widths of ≈ 60 nm in the bottom layer and ≈ 100 nm in the top layer, owing to the different Tc (Tc1<Tc2)” where Tc is the Curie temperature of each layer.

Although there are four potential paired layer bit states, a read-write head can only detect three, 1-1, 1-0 or 0-1, and 0-0, providing three-level recording from the two layers. Development work could enhance read-write head tech to distinguish between 1-0 and 0-1, enabling four-level recording from each bit area, as the authors say: “The magnetization corresponding to ↑↓ and ↓↑ was M ≠ 0, and should allow 4-level recording as the antiparallel states were easily distinguishable.”

Comment

The effective bit areas are the same in the upper and lower layers meaning that, for example, a 20 TB single-layer HAMR disk would become a 40 TB dual-layer HAMR disk. With three-level recording, the 20 TB HAMR disk would effectively become a 60TB drive, and, with 4-level recording, an 80 TB drive. This would change the relationship between HDDs and SSDs in $/TB and TB/RU terms.

Writing a bit area value is a two-pass operation, with the lower and upper layer areas written first, and the upper layer area written separately second. Thus it would take longer than today’s single pass writing operation. We understand the same issue would apply to reading the bit areas. This means that the disk’s IO speed would be slower than today’s single-pass HAMR drives. Its IO density, how much performance can be delivered from its storage capacity, would worsen, both from this and because the read-write head is the single channel to much higher capacity. Dual actuators might be needed to overcome this.

Considering that the disk is spinning underneath the read-write head during this two-pass operation, the second pass bit area is behind the first pass bit area to some degree. The authors say that they used a 4 meters per second (4 mps or 4,000 mmps) recording medium speed in their modeling.

We understand that the average track length of a 3.5-inch HDD is approximately 269.44 mm. It may be that a two-layer disk’s spin speed might need adjusting to reduce the offset between the first and second layer bit areas due to this movement.

The authors write that there were “written track widths of ≈ 60 nm in the bottom layer and ≈ 100 nm in the top layer, owing to the different” Curie temperatures for each layer.

Bootnote

The formal citation for the paper is: P. Tozman , S. Isogami , I. Suzuki , A. Bolyachkin , H. Sepehri-Amin , S.J. Greaves , H. Suto , Y. Sasaki , T.Y. Chang , Y. Kubota , P. Steiner , P.-W. Huang , K. Hono , Y.K. Takahashi.