Startup Cerabyte, which specializes in ceramic-coated glass storage, has built a demo workflow system and is looking for funding and partners to take the concept further.

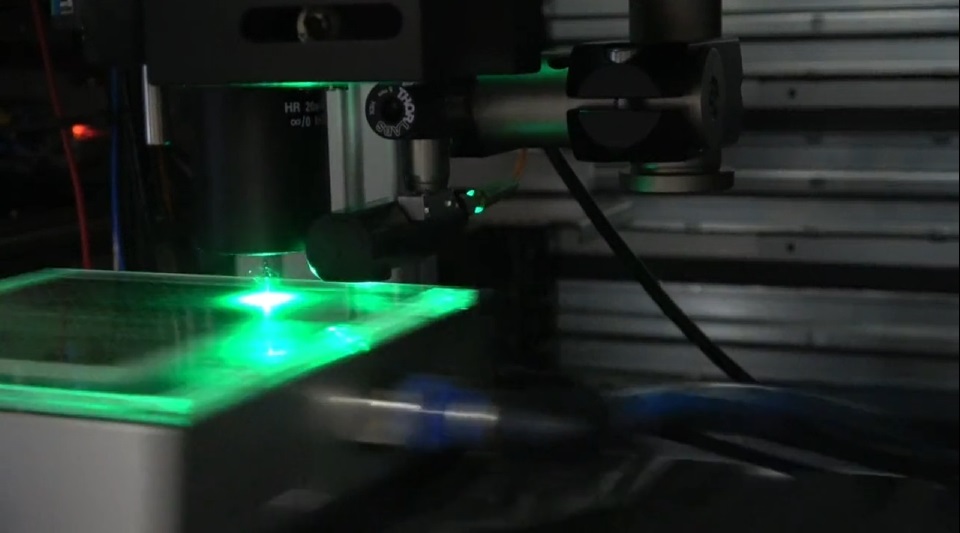

The German company has technology to create microscopic holes in a layer of a ceramic substance coating a square glass carrier. Holes are created with femtosecond laser pulses and laid down in a format similar to quick response (QR) codes with sequences of holes and no-holes representing binary zeroes and ones.

The glass carrier can be coated on both sides to increase data capacity, and several can be stacked inside a data cartridge. Cerabyte envisages a storage system composed of library racks and a write-read rack, with robotics used to transport the cartridges from the library racks to the write-read rack.

It could be likened to a tape library with the tape drives replaced by glass cartridge writer/reader devices, or an optical storage jukebox.

The demo Cerabyte system uses a datacenter rack form factor, and is shown in a video. The commentary explains that once a cartridge is brought to the write-read device, a carrier is extracted and placed on a platform or stage. This can move forward or backward underneath laser and reading camera components. These are focused on the glass carrier using mirrors and lenses.

The video commentary explains: “During the forward movement of the stage, a line of QR patterns is written, which are read back and verified during the backwards movement by a microscope camera. When a data carrier is fully written, it is returned into the cartridge which is then moved back to library.”

“The read workflow is similar whereby only the microscope camera is engaged and data is read in both directions of the stage movement. Error Correction and file allocation will work similar to other mainstream data storage technologies.”

We can readily understand that the write speed is based on two stage movements, forward for writing and backward for reading. Reading is based on both forward and backward movements.

The TBps write and read speeds will depend upon the QR code density. Cerabyte has mentioned 1 PB cartridges as a potential initial capacity with development through 10PB and out to 100 PB by using smaller bit sizes (holes) in the ceramic recording medium. It has discussed a progression from 100 nm to 3 nm bit sizes.

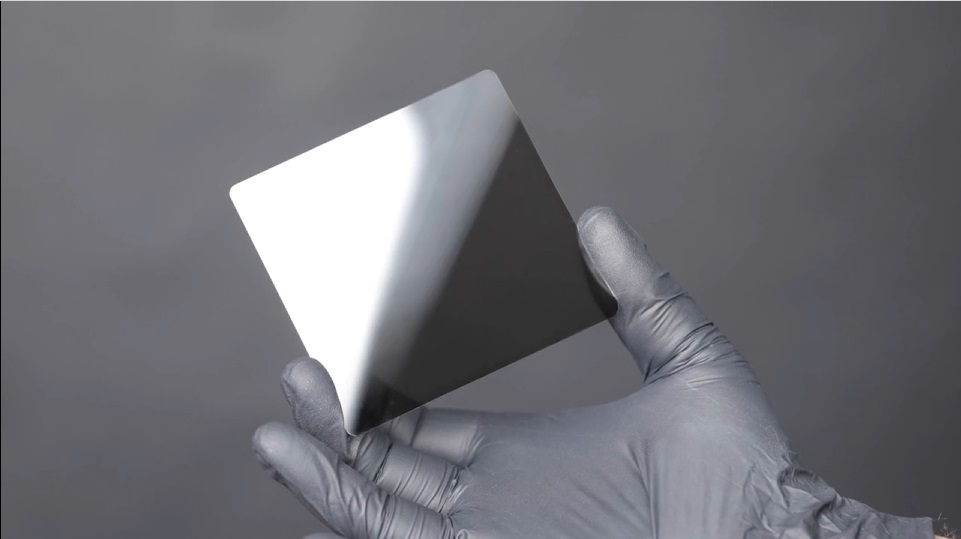

This ceramic medium has an initial thickness of 50 to 100 atoms and is said to be resistant to fire, cold, water, radiation, electricity, and other effects that can destroy data on tapes, disk drives, and SSDs. The glass carriers effectively last forever – we’re told – and, once in their cartridges, need no electrical energy for cooling or data maintenance. Moreover, unlike archival tape cartridges that require re-silvering, these carriers do not need any form of refreshing.

Cerabyte says its demo system was manufactured using commercial off-the-shelf components. Interested potential manufacturing partners, enterprises, research institutions, and institutional investors should contact Cerabyte by email at office@cerabyte.com.

Comment

The obvious comparisons we make with Cerabyte’s technology are Blu-ray optical disks and holographic storage technologies. Blu-ray writing creates pits in a recording medium which can be multi-layered. The spot size for the blue laser used is 580 nm with a 150 nm pit size. The pits are laid down in circular tracks on disks, whereas Cerabyte uses QR blocks on square glass carriers and has a smaller pit (hole) size of 100 nm. Holographic storage technology has never resulted in a commercial product due to manufacturing difficulties around the highly precise mirrors and lenses required.

The data capacity of Cerabyte’s demonstration square glass carriers or physical size is not known. The video suggests they are about 2-3 inches squared:

Microsoft has a Project Silica research effort looking at a glass-based archival storage medium and system for its Azure public cloud.