Blocks & Files met Siva Sivaram, President for Technology and Strategy at Western Digital, in San Jose. We discussed various aspects of disk drive technology, NAND and storage-class memory, and a fascinating discussion it was too, touching on energy-assisted drives, multi-actuators, penta-level cell flash and storage-class memory.

We summarise the disk drive technology discussion in this article and will follow it with one on solid state technology.

Energy-assist technologies

Microwave-assisted magnetic recording (MAMR) has been Western Digital’s public path to capacities greater than 16TB, along with shingled magnetic recording (SMR) to provide a further boost. The company’s recent 18TB and 20TB drive announcement reflected this.

Sivaram said: “Current PMR (perpendicular magnetic recording) doesn’t scale.” The jump from 14TB drives to the next-generation 18TB conventional and 20TB shingled generation was accomplished by adding an extra platter, taking the count to nine. WD also used some aspects of its MAMR technology – but not to the extent of beaming microwaves at the bit recording areas on the aluminium platters from a spin torque oscillator in the write head.

The read/write head has a ‘MAMR-like structure’ but areal density improvements derived from WD’s more accurately positioned micro-actuator heads. This and the addition of the extra platter took the capacity to the 18TB- 20TB level without full energy-assist technology.

By enhancing this current technology, WD can see its way to the next capacity level, which we assume is 22TB – 25TB, although Sivaram did not specify numbers. After that, WD will need to use a full energy-assist technology.

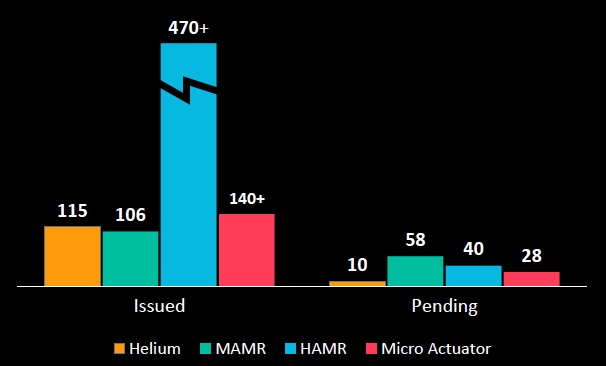

WD has not yet decided if MAMR or HAMR will produce the best mix of areal density, performance, reliability, and total cost of ownership. The company has spent $500m on HAMR research and development, according to Sivaram, with many filed patents, more than for MAMR technology.

Our take is that WD has the luxury of being able to defer the decision for a couple of years when the relative merits of each technology will be clearer.

Multi-actuator read/write heads and costs

Existing drives have a single actuator device moving the read/write heads across the disk’s platter surfaces and providing a single IO channel. Seagate is openly developing dual actuator technology to enable two IO channels and a consequent increase in IO capacity.

There may be a need for dual actuators in the disk drives that follow the 18TB – 20TB disk drive generation, according to Sivaram. But “up to the 18TB capacity level we didn’t need dual actuators as customers are not saying they need them.” It is pointless to add technology and increase cost when there is no customer demand, he added. “WD focuses on the total cost of ownership.”

Value-based pricing

This led Sivaram to discuss pricing; “Disk capacities are scaling beautifully. We want to move towards value pricing.” Customers are getting substantial added value from the linear scaling in disk drive capacity to the current levels, according to Sivaram. They would get even more from future capacities.

With larger capacity drives the manufacturing cost in $/TB terms comes down. He suggested that, perhaps, it is time to think about moving from manufacturing cost-based pricing centred on $/TB towards value-based pricing: “$/TB is no longer the right metric.”

A customers gets more value from a larger capacity drive, he said. “They can monetise more data.” This extra value could be larger than the sheer savings of the lower $/TB cost that WD can pass on. In that case WD could pass on only a proportion of that cost-saving to the customer and so charge for some of the extra value.

Host-managed shingled drives

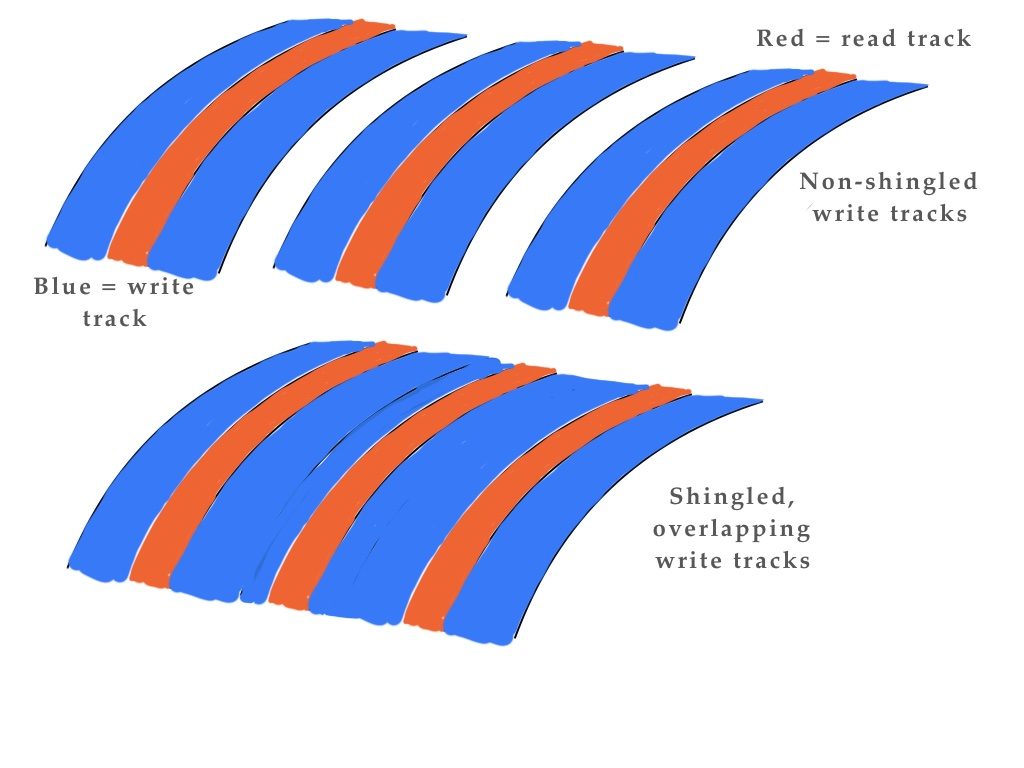

Shingled magnetic recording (SMR) increases disk capacity by overlapping write tracks so that more can be crammed onto a disk platter without affecting the narrower read tracks. Why is a disk’s write track wider than a read track?

Sivaram said it was due to atomic vibrations in the recording media. A bit’s atomic vibrations have the potential to affect a neighbouring track bit’s value, changing its value. Consequently, bits have to have a moat around them and along the tracks to absorb the vibration effects. This stops them affecting bits in neighbouring tracks, and makes the tracks wider. Once written, tracks can be read by scanning a narrower central section. They can also can be partially over-written by the next track – the shingling effect – without affecting a track’s readability.

If disk drive tracks did not have to cope with atomic vibration, write tracks would be the same width as read tracks and shingling would not be necessary. At absolute zero there is no atomic vibration and the read and write tracks could have the same width. As the temperature rises above absolute zero, atomic vibration starts and its amplitude increases as the temperature rises. Hence write tracks have to widen to cope with this.

Shingling drives are built with the shingled tracks in circular zones separated by empty areas. This means that, when data is rewritten, only the group of overlapping tracks in a zone have to be changed and not the whole drive. Thus process of rewriting data in a zone of overlapping tracks can be handled by the drive controller or by the host server system.

When shingling is managed by the disk drive controller no changes to the host systems software are needed. The shingled drive is a drop-in replacement for a conventional, non-shingled drive. Host-managed shingled drives on the other hand do require the host system’s software to change so that it manages the shingled drive write process. This has limited their adoption.

In Sivaram’s view the adoption is starting to happen: “The benefits of the additional terabytes tempts customers. Adoption is starting to happen. Lots more customers are comfortable with it.”

TL:DR

Western Digital sees no need to rush to delivering new technology when it is not required by customers and when it can match and surpass competitors with current technology. It regards itself as the disk industry’s areal density leader and will closely watch drive technology costs, and customer needs and benefits, to decide when to move ahead.