Seagate began shipping 16TB Exos nearline drives in June last year, before Western Digital had even announced its own 16TB drive tech. It took another eleven months for WD to ship UltraStar HC550 16TB and 18TB drives. And the key to getting the drives out of the door was a hitherto unexplained technology called ePMR.

WD has now revealed some ePMR details in a short document, which was flagged up to us by analyst Tom Coughlin in a subscription mailing. We’ll explain why ePMR was necessary for WD and then take a closer look at the technology.

Today’s perpendicular magnetic recording (PMR) technology is reaching the end of the technology road. Its ability to make bits smaller is compromised by bit value stability becoming unreliable as the areal density approaches 1TB/in².

For over a year WD has talked up its forthcoming microwave-assisted magnetic recording (MAMR) technology as a means to overcome this obstacle. MAMR uses microwaves to write data to a reformulated and more stable magnetic material that can pack smaller bits packed more closely. The technology provides a path to 40TB drives, according to WD.

However, WD did not use MAMR in the UtraStar HC550s, plumping instead for ePMR to increase the areal density of the drives. We infer that the company chose this stopgap because of MAMR issues, but we have no insider knowledge here.

Whatever the reason for implementation, ePMR enabled the 18TB UltraStar HC550 (1,022Gb/in²) to achieve 13 per cent areal density increase over WD’s 14TB HC530 drive (904GB/in²). WD is now in a race with Seagate to ramp up 18TB nearline disk drive production.

Bias current

This ePMR tech is briefly explained in a WD technical brief, Continuous Innovation for Highest Capacities and Lower TCO, which states the HC550 and HC650 “introduce the industry’s first Energy-Assisted Magnetic Recording (EAMR) technology.”

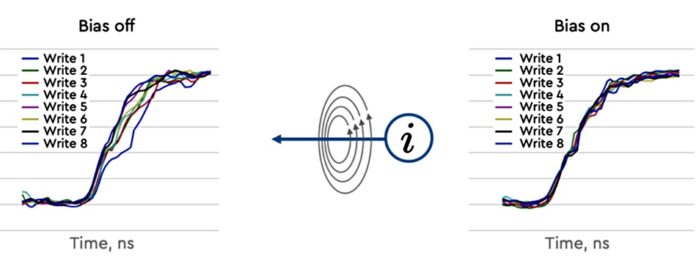

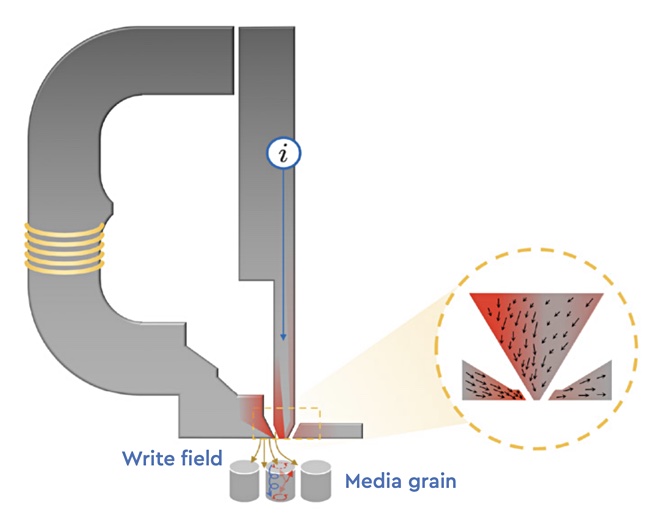

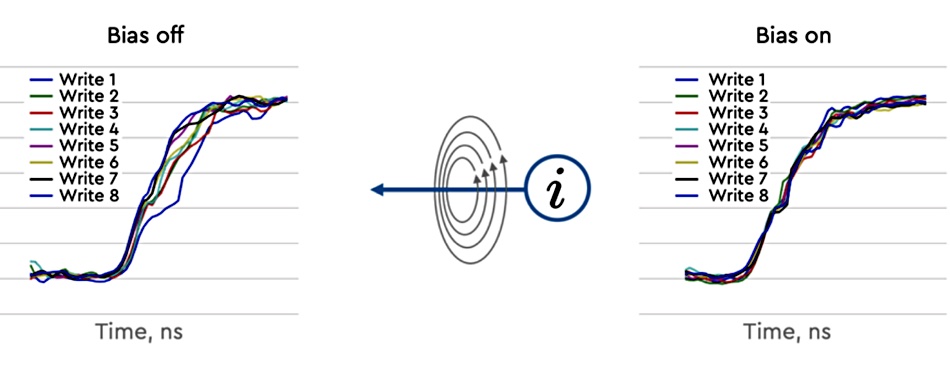

This is ePMR, which “applies an electrical current to the main pole of the write head throughout the write operation. This current generates an additional magnetic field which creates a preferred path for the magnetisation flip of media bits. This, in turn, produces a more consistent write signal, significantly reducing jitter.”

The need for such a bias current is that disk recording heads can provide an inconsistent magnetic field to bits because their write currents can be distorted – so-called “jitter”. This effect makes bit value signal recognition more difficult and worsens as bits decrease in size and are placed closer together.

A WD chart shows the effect of the bias current being applied, with the write process becoming more consistent:

These HC550 and HC650 disk drives also use triple-hinged actuators to enable finer control of the read/write head’s placement on the disk platter.

Blocks & Files expects WD to announce full-scale MAMR drives with 20TB capacities and higher by the end of the year.