Western Digital clarified its hard disk drive (HDD) technology road map at a Storage Tech Field Day session on January 22, 2020, but managed to avoid revealing how its latest ePMR technology works.

At the moment HDDs are in a perpendicular magnetic recording (PMR) era, with longitudinal bits set upright – perpendicularly – in the platter recording medium. The two great HDD manufacturers, Seagate and Western Digital, are both espousing energy-assisted technologies to get past approaching areal density limits with PMR. Essentially, due to growing thermal instability, PMR bit values become less and less reliable as 3.5-inch disk platters move into the 2TB/platter areal density level and beyond.

Energetic assistance

To move past that, some form of more stable recording media will be needed, with bit values written while the bit location in the media is either heated (HAMR or heat-assisted magnetic recording) or excited by microwaves (MAMR or microwave-assisted magnetic recording.) The heat or microwaves lower the medium’s coercivity (resistance to magnetic polarity change) which returns to a higher value at room temperature. This makes the bit value stable.

Seagate is working on developing HAMR as its next main recording technology while Western Digital has settled on a 3-phase approach. This was outlined by WD’s Carl Che, VP HDD Technology at the session:

- Energy-assisted PMR (ePMR), as used in its 18TB DC HC550 drives,

- MAMR,

- HAMR.

Che did not say how energy-assistance worked with ePMR. He did say: “When we worked on MAMR we found there is a new physical phenomenon we can utilise. And by combining this phenomena we created a new recording scheme called ePMR; standing for energy-assist PMR.”

Coming drives will use this technology, which is a stepping stone or building block based on MAMR technology, enabling full MAMR in the future. Che wouldn’t say more about it but: “We will have a product coming very soon and I’m definitely looking forward to having conversations on that.”

MAMR may give way to HAMR in WD’s roadmap; that decision has not been made yet.

ePMR roadmap

With the 9-platter, 18TB HC550, the energy assist is not about areal density, but rather reliability. Che said the HC550 will come this year and WD is simultaneously working on the next generation – 20TB and beyond – to exploit the ePMR gains and drive areal density upwards. He mentioned that the surface width of an ePMR track is in the 50nm area. These drives do not need very much extra electricity to operate at all.

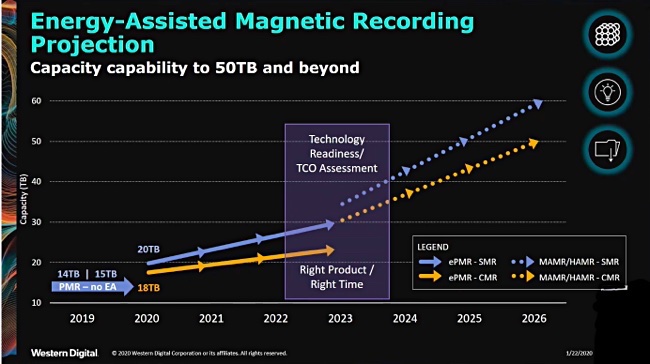

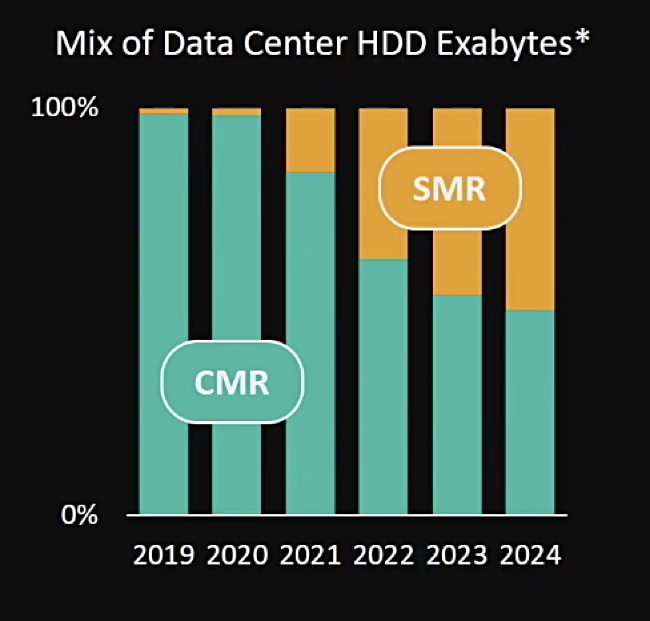

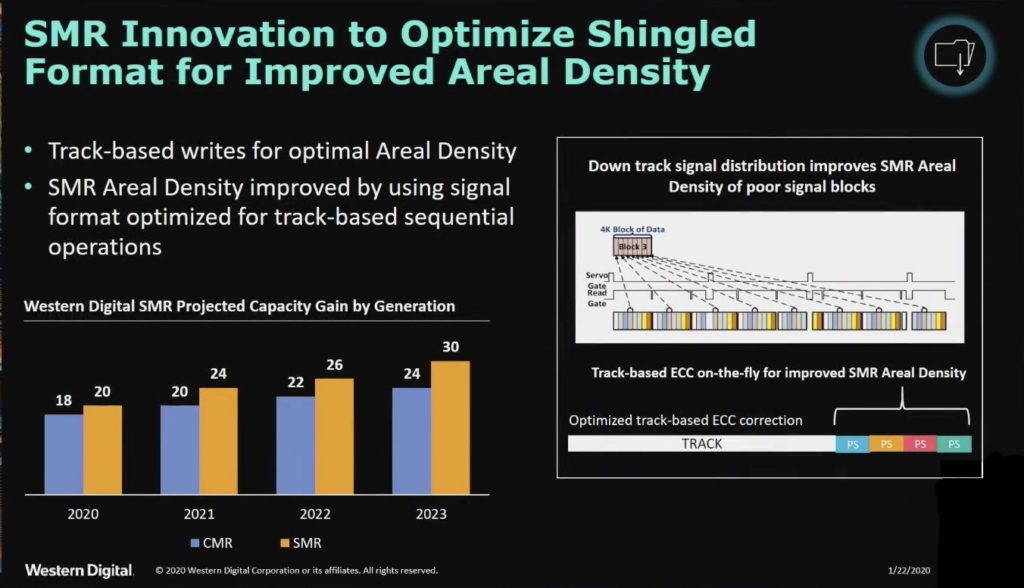

The application of Shingled Magnetic Recording (SMR), with partially overlapping write tracks, will add a 20 per cent capacity uplift (24TB). After that the roadmap shows a progression with ePMR to about 24TB in 2023 and 30TB with shingling.

Then there’s a jump to 30TB with non-shingled full energy assist – MAMR or HAMR – and 34TB with shingled MAMR or HAMR. From this point the roadmap progresses to 50TB (non-shingled) and 60TB shingled in 2026.

Read/Write heads

Such a progression needs read/write head developments as well as media technology progression. The 2cm long head has to stay on track with plus/minus 1nm positioning accuracy.

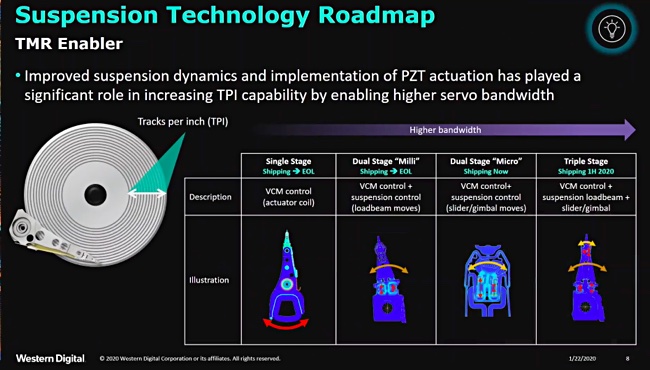

These heads need to be able to position themselves precisely over a track density of up to 500 tracks per inch (TPI) and beyond.

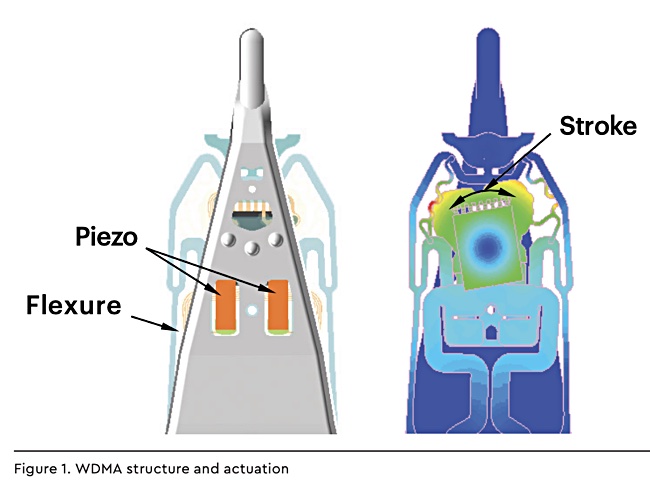

WD has a dual-stage micro actuator diagram (WDMA) showing dual piezoelectric strips. When differential voltage is applied to the WDMA, one piezo element expands as the other contracts. This action causes a slight rotational motion of the read-write head.

Western Digital is currently shipping dual stage micro actuators with triple stage ones due in the Spring/second half of 2020 (HC550), with the required 500 TPI positioning accuracy and beyond. These move in three places along the head assembly; where it is mounted (as in single stage actuator), along the loadbeam (as in dual-stage actuator), and at the tip of the actuator (slider/gimbal).

The optimised use of these three controls should reduce the seek time and, Che said, “help our overall (IOPS) performance).”

Track-based writes for SMR

Che said areal density in shingled drives was improved by using on-the-fly track-based ECC. There is ECC on the data blocks and ECC on a whole track.

This enables improved track read and write accuracy. WD predicts it will get a 20 per cent capacity gain by shingling ePMR out to 2023, with 30TB SMR drives. The chart shows four generations of ePMR drives, starting with the 18TB HC550 this year, and followed by 20TB, 22TB and the 24TB product. The commensurate SMR product stages are 20TB ( HC650), 24TB, 26TB and 30TB.

Reducing IO Density

The increased number of tracks and bits/track, meaning overall increased areal density, reduces the number of IOPS/TB. Che said: “When we drive the capacity bigger you will see the unit of IO will reduce; that’s given.” He said WD’s hypercloud customers know this.

He said Intelligent IO queue management by the drive can be used to reach a target IOPS performance while maintaining latency at higher queue depths (4, 16, etc.)

Che didn’t mention multi- or dual-actuator drives which Seagate is developing to increase IO density. WD did discuss dual actuators last year for example, and Blocks & Files think it will use them eventually.

He said WD has a clear vision of how to get to 50TB and beyond – except that the decision about whether to use MAMR or HAMR post-2023 hasn’t yet been made. And we still don’t know how ePMR works.