Researchers at nano- and digital technology R&D center IMEC are suggesting memory could become liquid in the future.

Engineering boffins at Belgium’s IMEC (Interuniversity Microelectronics Centre) presented a paper on liquid memory at the 2022 International Memory Workshop (IMW). Maarten Rosmeulen, program director of Storage Memory at IMEC, identifies DNA storage as a post-NAND high-density but slow archival technology in an IMEC article. He proposes that liquid memory could replace disks for nearline storage at some point in the future.

Two types of memory, colloidal and electrolithic, are said to have the potential for ultra high-density nearline storage applications and might have a role between disk and tape from 2030 onwards “at significantly higher bit per volume but slower than 3D-NAND-Flash.” Rosmeulen says: “We anticipate that with these approaches, the bit storage density can be pushed towards the 1Tbit/mm2 range at a lower process cost per mm2 compared to 3D-NAND-Flash.”

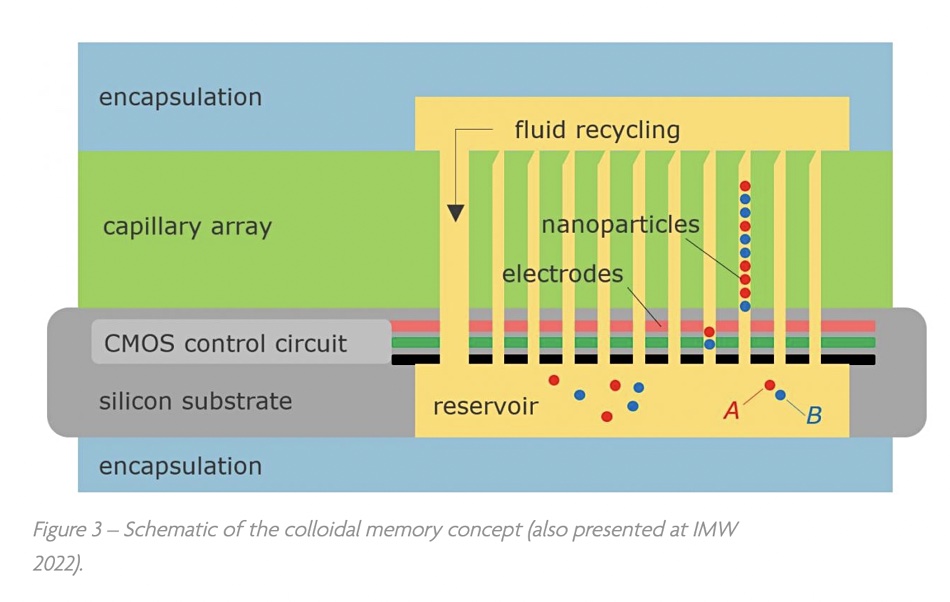

In colloidal memory, two types of nanoparticles are dissolved in water contained in a reservoir. They carry data symbols. The reservoir has an array of capillaries through which the nanoparticles flow one at a time. “Provided that the nanoparticles are only slightly smaller than the diameter of the capillaries, the sequence in which the particles (the bits) are entered into the capillaries can be preserved.” The bit sequences encode information and the nanoparticles can be sensed by CMOS peripheral circuit-controlled electrodes at the entrance to each capillary tube for writing and reading.

Frequency-dependent dielectrophoresis is being investigated as a write mechanism. “A selective writing process can be created by choosing two particles that respond differently to the applied frequency (attractive versus repulsive).” R&D with polystyrene nanoparticles is ongoing “to fine tune the concept and provide the first proof of principle on a nanometer scale.”

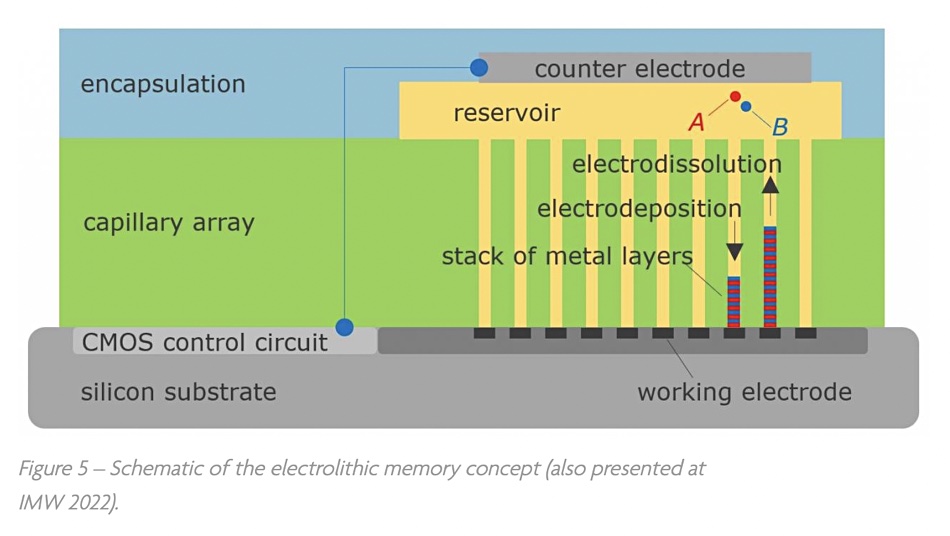

Electrolithic memory also has a fluid reservoir with an array of capillary tubes. Two kinds of metal ions – A and B – are dissolved in it and electro-deposition and electro-dissolution techniques are used for reading and writing information.

There is a working electrode at the base of each capillary tube, which is made of an inert metal like ruthenium, and the reservoir also has a single counter electrode. A CMOS integrated circuit connects to the dense array of working electrodes. The common counter electrode plus the reservoir and a working electrode form an electrochemical cell for each capillary tube.

The articles says: “By applying a certain potential at the working electrode within the capillary, thin layers of metal A can be deposited on the electrode. Metal B will behave similarly but deposits at a different onset potential – determined by its chemical nature.” Information can be encoded in a stack of alternating layers on each working electrode. For example, “1nm of metal A can be used to encode binary 0, while 2nm thick layers of A encodes a binary 1. A layer of metal B of fixed thickness (e.g. 0.5nm) can be used to delineate subsequent layers of A.”

Rosmeulen says: “These new liquid-based memories are still in an exploratory research stage, with the electrolithic memory being the most advanced. Nevertheless, industry has already shown considerable interest in these concepts.”

HJe adds: “To become a viable storage solution for nearline applications, the technology must also have adequate response time, bandwidth (e.g. 20Gbit/s), cycling endurance (103 write/read cycles), energy consumption (a few pJ to write a bit), and retention (over 10 years). These evaluations will be the subject of further research, building on IMEC’s 300mm liquid memory test platforms with both colloidal and electrolithic cells in different configurations.”