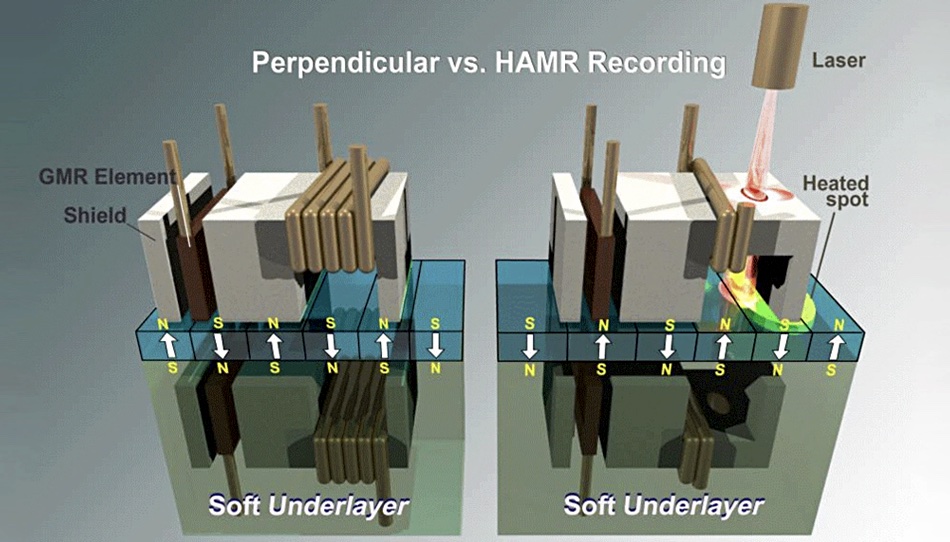

Heat-assisted magnetic recording (HAMR) needs new recording media on disk platter surfaces. One solution is in the works from Seagate, which has partnered with platter and media supplier Showa Denko to develop it.

Of the three disk drive makers, Seagate is the only one which has committed to move to HAMR technology directly from current PMR (perpendicular magnetic recording) technology without using MAMR (microwave-assisted magnetic recording) as a multi-year intermediate step. HAMR media has to withstand repeated high-intensity bit area heating and cooling without degradation.

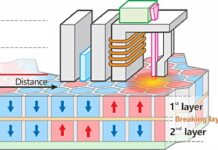

The bit area heating is needed to overcome the resistance or coercivity of the material needed to store magnetic charges in very small bit areas stably over time, at areal densities in the 2TB-plus area per disk platter. PMR media cannot operate reliably at such areal densities.

Showa Denko recently developed a FePt (iron platinum) magnetic material that could provide the ultra-high ordering temperature needed by HAMR. This would be difficult to achieve on the surface of HD media coated with conventional magnetic material. Seagate will evaluate this FePt-based magnetic material, as well as new material to be jointly developed in the future. The two expect their alliance will accelerate the development speed of HAMR-related technologies for both companies.

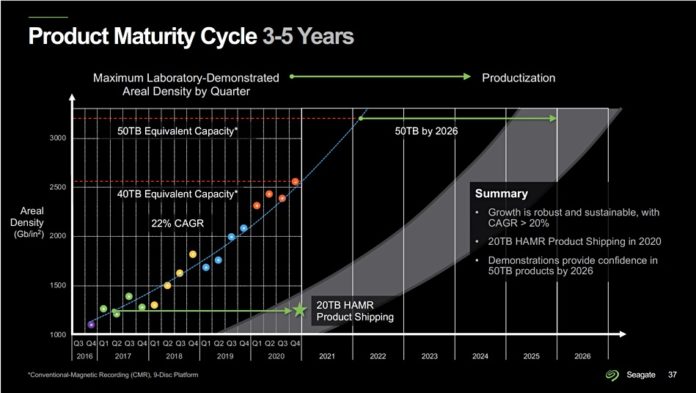

Up until now Seagate has been relying on HAMR technology created in-house to take its disk drive capacities past PMR’s 16TB–18TB limit, and onwards to 40TB and beyond. It is shipping some 20TB HAMR disks for customer testing, but has not fully committed yet to HAMR technology.

Neither company provided an executive-level statement about their partnership.

Toshiba is sourcing MAMR disk drive platters from Showa Denko, which makes the Japanese firm an important player in the HDD supply chain.