Flux control MAMR gives Toshiba two more real density increase generations from current disk drive recording technology without having to develop a new recording medium.

Toshiba found that fully reversing the direction of a spin torque oscillator, intended for use with MAMR technology, actually made conventional recording more efficient — providing a 20 per cent areal density gain.

Toshiba Electronics Europe senior manager Rainer Kaese briefed Blocks & Files on its Flux Control – Microwave Assisted Magnetic Recording (FC-MAMR) technology, adding clarity and numbers to the picture we had worked out from reading a Toshiba research paper.

He said FC-MAMR “was an easier leap; an intermediate step,” to full MAMR.

Current perpendicular magnetic recording technology (PMR) was, Toshiba thought, going to run out of areal density increase possibilities after it achieved a 16TB nine-platter MG08 drive. The bits in the recording medium would have too weak a magnetic signal if they became smaller to increase the platter capacity. This signal would be hard to read (poor signal to noise ratio) and be unstable.

This was the reason Toshiba, like Western Digital, planned to move to Microwave Assisted Magnetic Recording (MAMR) technology which has two technology thrusts: first, a more stable magnetic recording medium would be developed that could sustain smaller bit areas; and second, because it was then harder to write bits, microwaves would be fired at the bit area to overcome the higher-than-PMR write resistance (coercivity).

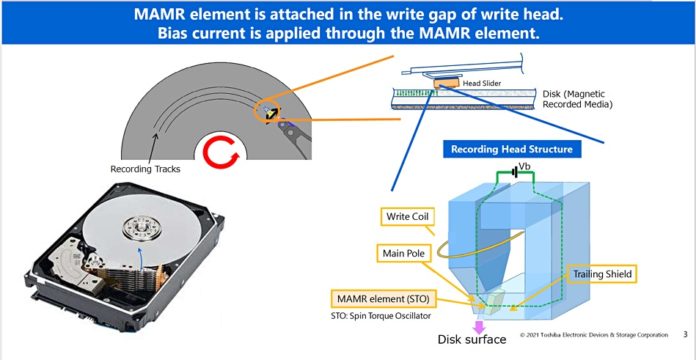

This requires a microwave-generating spin torque oscillator (STO) device, activated by a bias current, to be added to the drive’s read/write heads to enable the smaller bits to be written. However, there was an unanticipated effect and benefit.

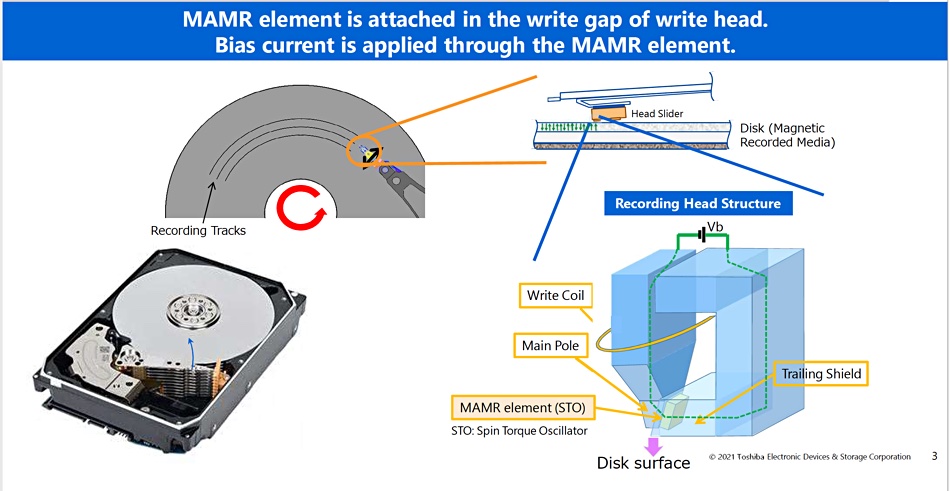

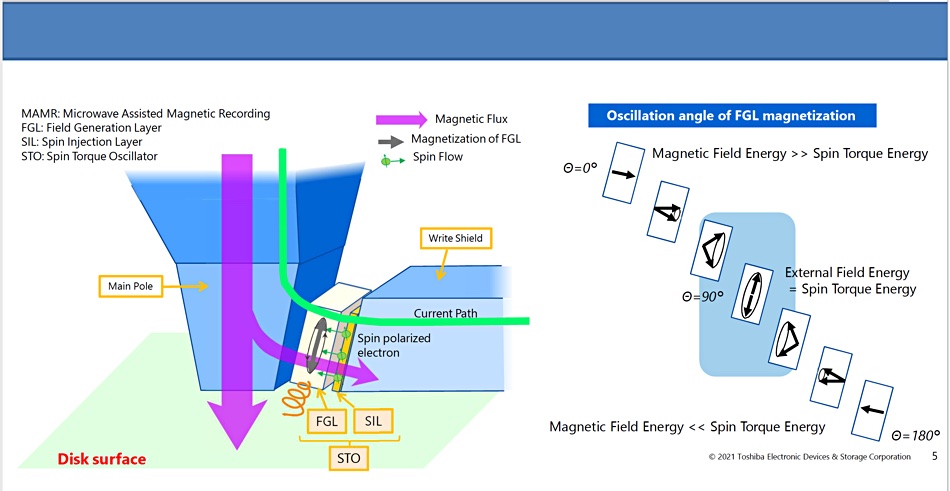

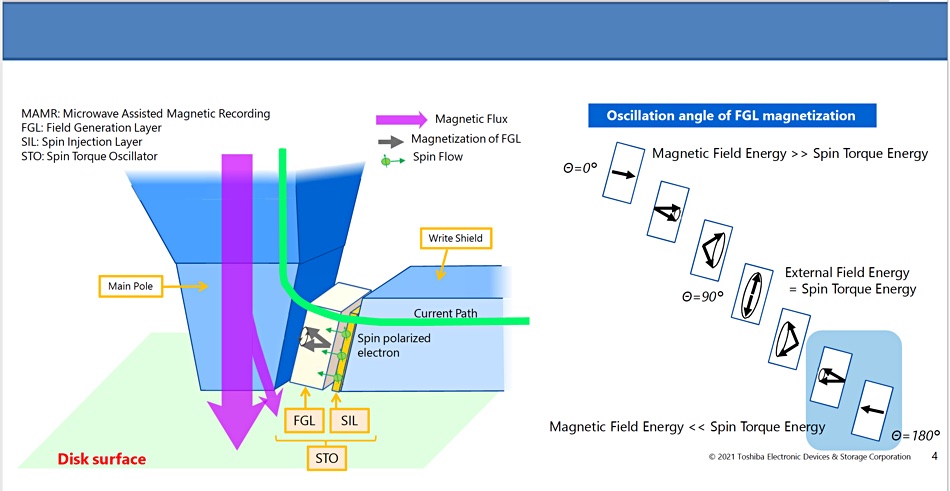

A MAMR-equipped write head has a main writing pole which projects magnetic energy or flux (purple arrowed line on diagram above) at the platter recording medium when it needs to write a bit. There is a space between the main pole and a trailing shield. The tiny STO is inserted into this space. The STO has two components: a microwave Field Generation Layer (FGL) and a Spin Injection Layer (SIL), which are shown in another Toshiba diagram (see below).

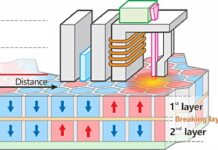

The FGL produces magnetisation using spin torque energy — incoming spin-polarised electrons from the SIL. The resulting magnetic field energy has an oscillation angle (characterising its flux) which varies from zero to 180° and onwards. At 0° (no oscillation) the energy flows in a straight line. At 45° it oscillates around a central point in a circle but points in the same general direction. At 90° it oscillates up and down a central point with a 90° separation between the 0° line and new line. This is the desired MMR state as the diagram illustrates below, and causes the STO to fire microwaves (orange spiral line) at the target bit area.

This diagram shows magnetic flux (purple line) plunging down into the platter recording medium from the write head, with a side flow through the microwave-producing STO into the Write Shield.

But, at a 180° oscillation angle the STO’s magnetic field energy flows in a straight line again and in a reverse direction to the 0° line. This is the key effect that the Toshiba research engineers detected and it, crucially, causes the strength of the write head’s magnetic flux to be increased (shown as an allied purple line in the diagram below).

The STO produces no microwaves in this case, but they are not needed as this flux control effect can produce a 20 per cent increase in areal density beyond the 16TB, nine-platter reference level with existing PMR recording. Bits are written more strongly with FC-MAMR and can be made smaller without overwhelming the bit signal with surrounding noise.

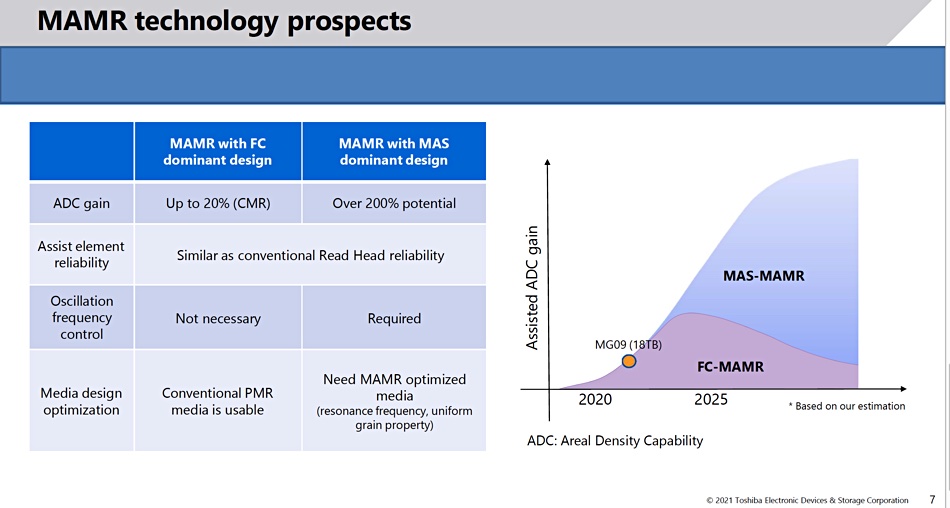

Toshiba has used this FC-MAMR technology to produce its18TB, nine-platter MG09 disk drive and Kaese implied a 20TB follow-on product successor is coming; possibly to be called, we think, an MG10.

To go beyond the 20TB areal density level, Kaese said, full MAMR will be needed, with a new recording medium having to be developed.

He said full MAMR has the potential to have a more then 200 per cent areal density uplift on the 16TB, nine-platter reference level disk; a 3X or so increase to 48TB–50TB disk drives. Kaese pointed out: “We do not see any obstacle to this.”

Comment

Western Digital has also produced a part-MAMR drive — the 18TB UltraStar HC550 — saying it uses ePMR technology. The technology, a Western Digital document states, “applies an electrical current to the main pole of the write head throughout the write operation. This current generates an additional magnetic field.” WD uses the unit to reduce write signal jitter and so produce a better written bit. That sounds pretty similar to the outcome of Toshiba’s bias current/STO technology.

Seagate, with its Heat-Assisted Magnetic Recording (HAMR) technology, has no similar intermediate step from current PMR to HAMR, and thus is denied the production cost comfort of having lower-cost intermediate staging steps before going into full energy assistance.