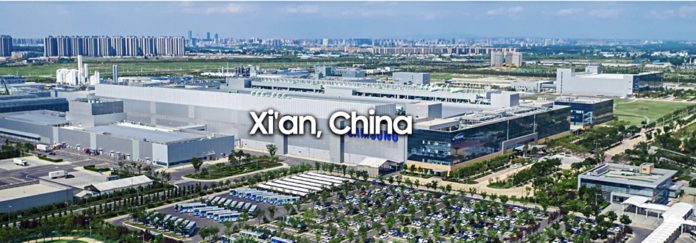

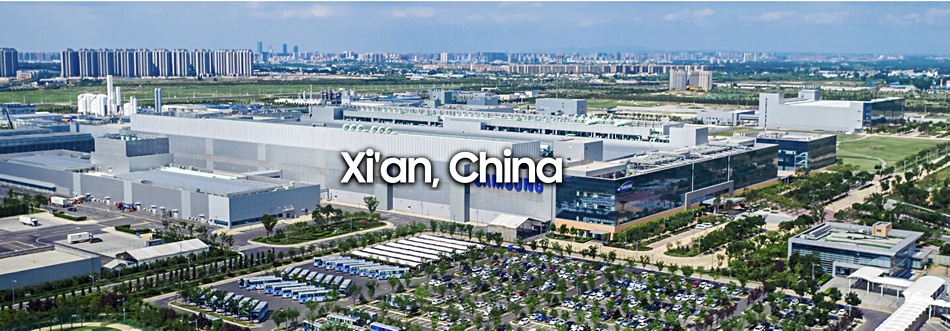

Samsung has begun making NAND wafers at its new flash foundry in X’ian, China – on schedule despite the Covid-19 pandemic.

The new plant will manufacture fifth generation Samsung 3D V-NAND, with 90+ layers and a 256Gb die capacity. Samsung is targeting 20,000 wafers per month initially and will increase output to 65,000 wafers.

So how many flash memory chips does that equate to? Samsung and other NAND producers typically do not reveal die dimensions as competitors can use this figure to work out their cost. But to give you a very rough idea, 65,000 wafers with about 700 dies per wafer equals 45,500,000 chips per month.

(Samsung’s 48-layer V-NAND has a die size of 99.84mm squared, equivalent to a maximum of 708 dies on a wafer. As 3D NAND layers extend upwards the die count on a wafer should remain fairly consistent around the 700, other things being equal. Also, note that some dies fail testing – so yield per wafer is lower than the theoretical maximum.)

Samsung plans to introduce gen 6 V-NAND in June, still using the 256Gb die and with 100+ layers. A seventh generation will follow, with a 512Gb die utilising 200+ layers.

Samsung makes V-NAND at its Pyeongtaek and Hwaseong foundries in South Korea. Pyeongtaek will “soon” move to gen 6 V-NAND, the company says.

The new Xi’an fab marks the completion of a $7bn investment announced in August 2017. Samsung operates another fab in Xi’an, employing 3,300, which produced its first wafers in 2014. The company plans another investment of $8bn to double output to 130,000 wafers per month. We don’t have timing details.